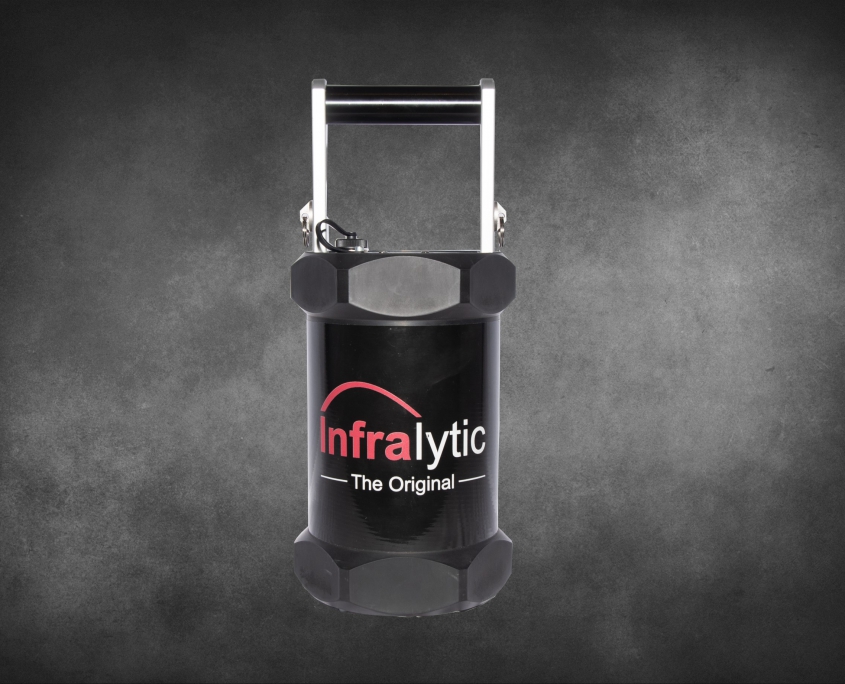

Welcome to Infralytic

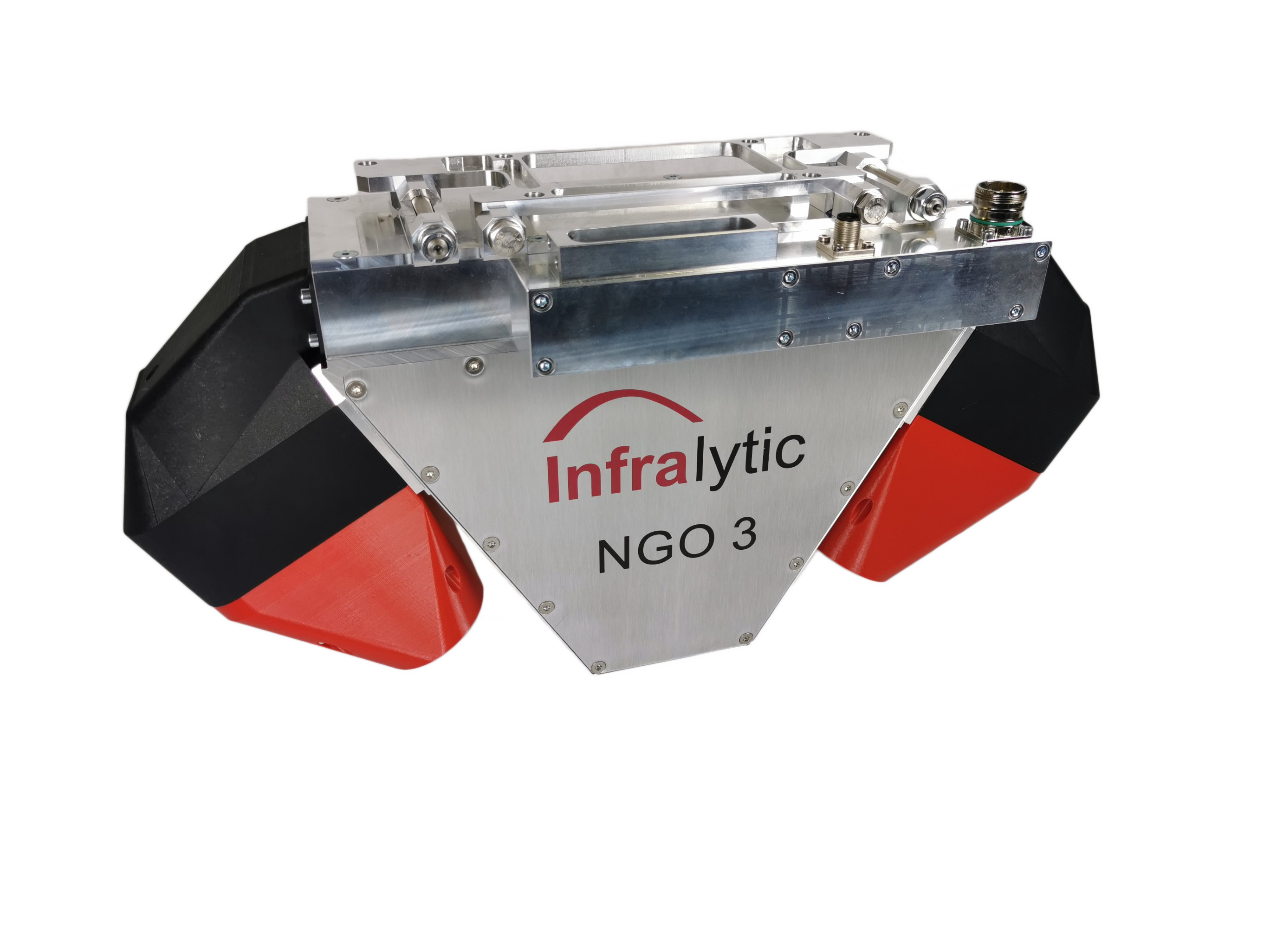

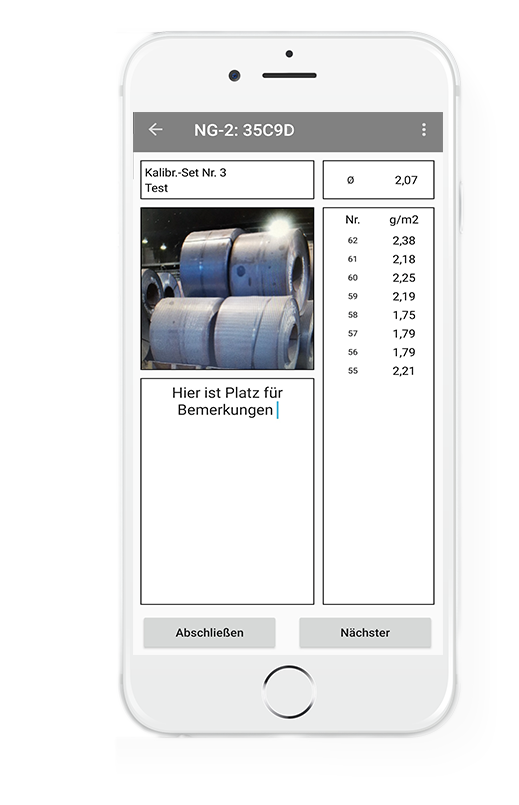

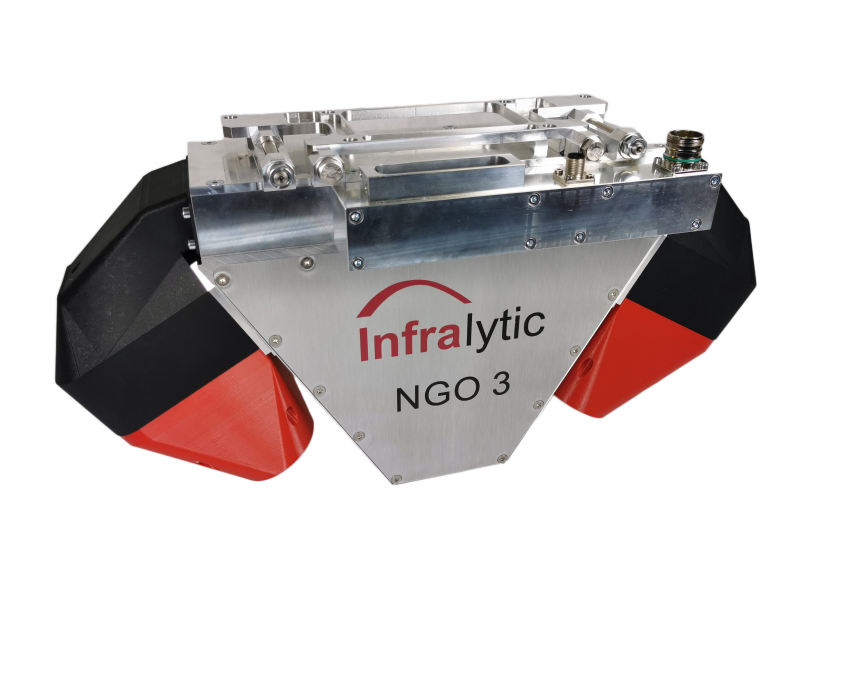

Infralytic GmbH is an owner-operated, medium-sized company based in Marburg and Lübeck. We offer innovative and high-quality measurement technology for unusual and demanding tasks. Thanks to our 3o years of experience in dealing with infrared spectroscopy and the know-how of our highly qualified employees, we guarantee non-destructive sensors at the highest level. Increasingly complex requirements lead to the constant development of new sensors. We will find the ideal solution for each of your tasks.

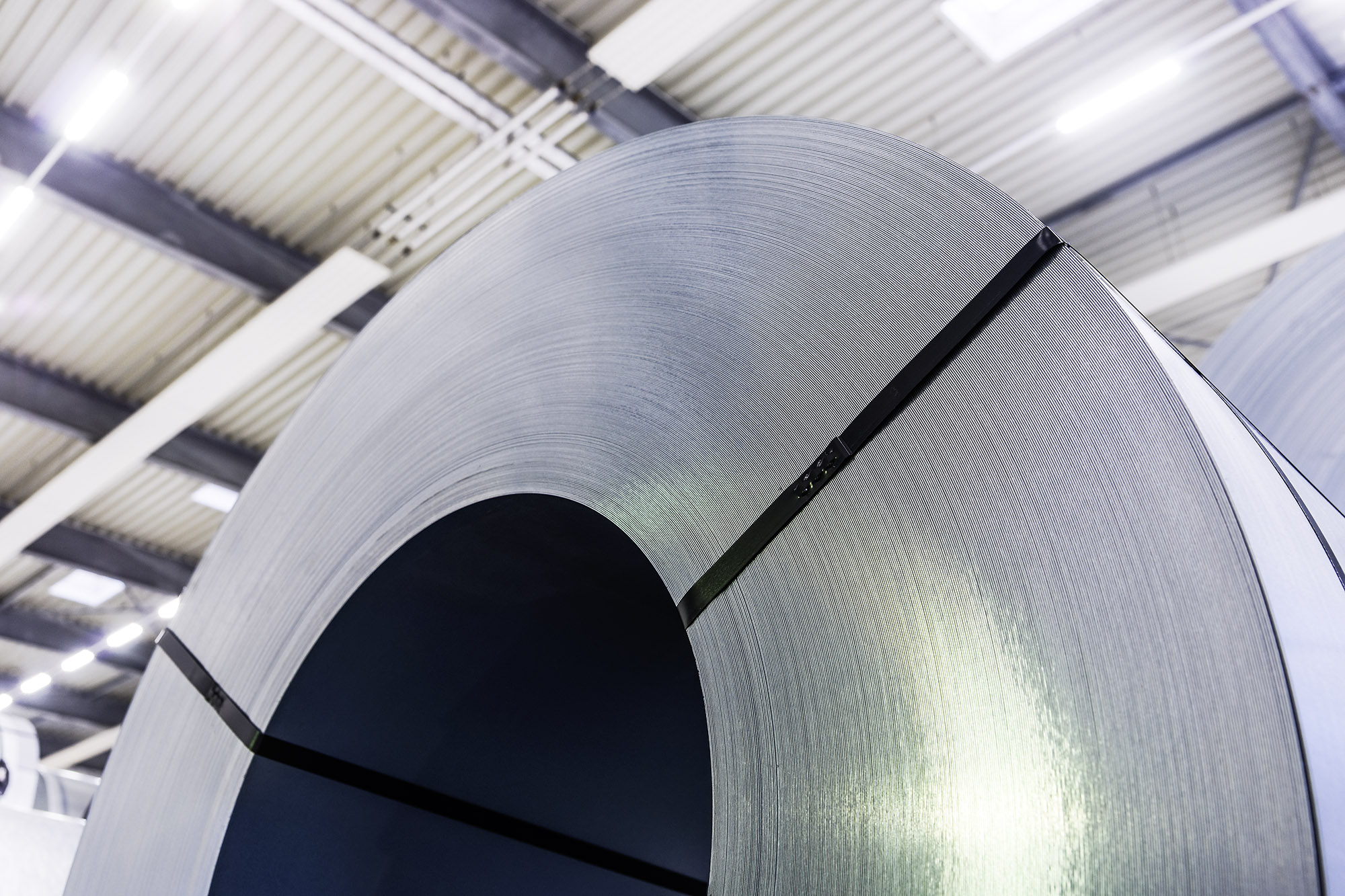

Here you will get an overview of the various applications of our sensors.