Any questions? We look forward to your question.

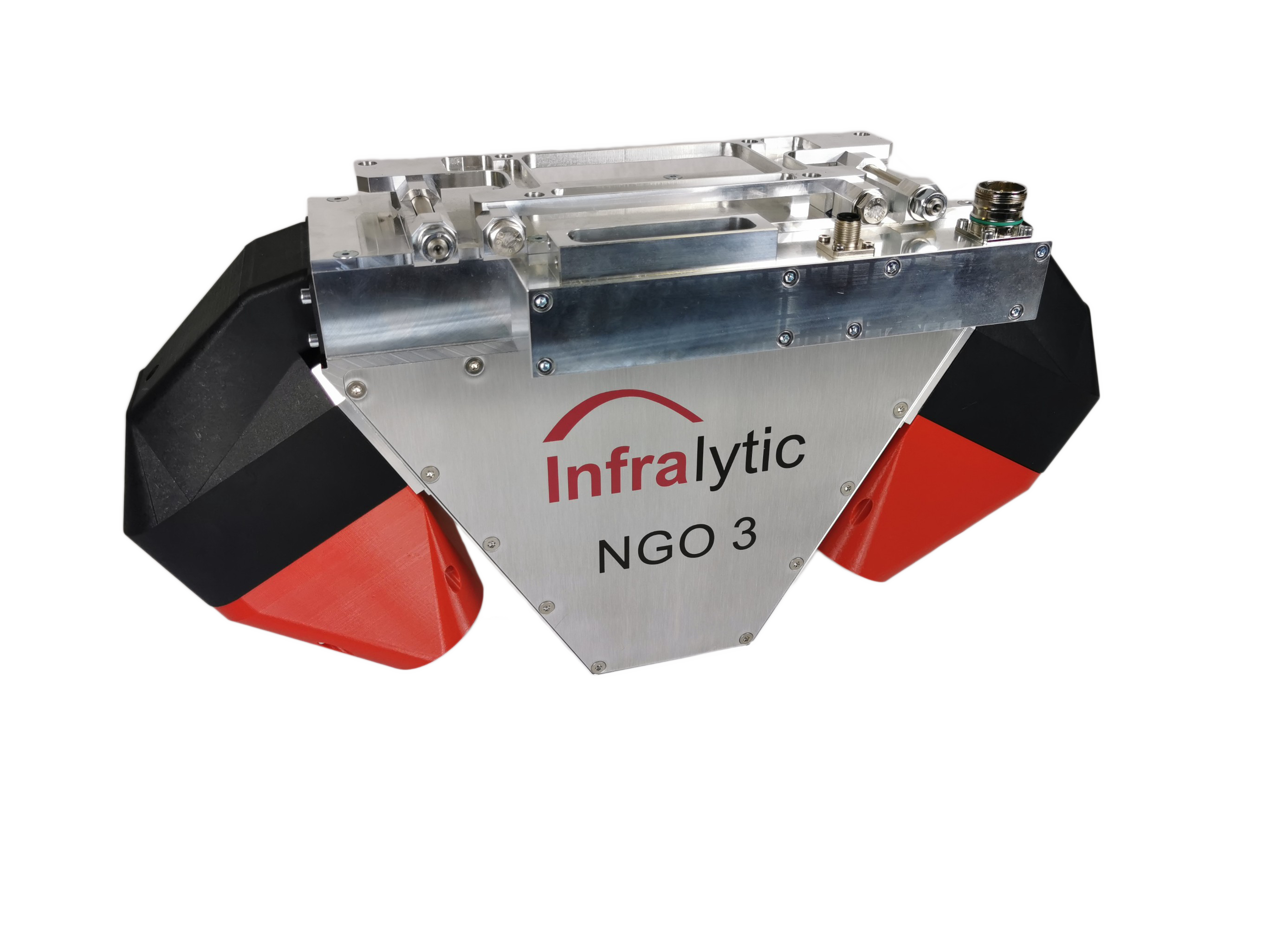

New NGO3-W measuring head for contact free water film measurement in moving processes.

Companies are facing rising demands to improve their energy balance. The rolling of slabs requires a lot of energy. After the rolling process, the strip is wound up. Here, the emulsion required for rolling is blown off at great expense and the strip is dried using radiant heaters and fans.

Our water measuring head NGO3-Water measures the remaining amount of water on the belt in real time while the belt is being wound at production speed. With a distance to the strip of 200 mm the measuring head can e.g. be mounted between the last scaffold and the reel.

The information about the measured amount of water and lubricant on the belt is shown in separate displays in mg / m² and directly on the monitor of your operator. This means that the drying of the belt can be adjusted according to the measured values and it does not have to be heated and blown excessively. The large danger of water ending up being wrapped in the coil is history.

- non-contact measurement in real time

- internal automatic continuous validation review

- color, graphic display

- Independent of the line speed

- Band vibration compensation

- 200 mm safety distance between measuring head and material

- Independent of residual oil

- IP 65

Special sensor for measuring emulsions.

The sensor is used e.g. in

- Heavy plate rolling mills

- Continuous casting plants

- Hot rolling mills

Measurement method:

Infrared spectroscopy

Measuring range:

0.05 – 6 g / m²

Measurement accuracy:

up to 0.7 g / m²: ± 0.025 g / m²

from 0.7 g / m²: ± 3.5 %

Repeatability:

± 5 nm without smoothing (120 Hz)

± 0,8 nm with smoothing

Measurement resolution:

up to 0.01 g / m²

Surfaces:

all that are not extremely shiny e.g.

Cold strip, hot-dip galvanized,

electrolytically galvanized, phosphated,

aluminized ZnMg surfaces, galvanized

Aluminum – uncoated, pre-treated

Remaining lubricants being tolerated:

Mineral oil, tixotropic mineral oils, hotmelt, waxes,

other organic lubricants after special calibration

Measuring distance:

200 mm + 20 / - 20 mm

Measurement frequency:

up to 120 Hz

Speed off thetransversing unit:

0 to 2 m / s

Ambient temperature:

+ 0 °C to 55 °C

Cleaning interval:

up to 12 months (depending on the environment)

Protecion class:

IP 65