Any questions? We look forward to your question.

Traversing continuous oil layer thickness measurement

Infralytic is considered to be the most innovative developer and manufacturer in oil layer thickness measurement technology.

Our more than 20 years of know-how lies in the non-contact measurement of oil film layers on steel and aluminum.

The inline sensors are specially designed for automated and continuous measurement of the oil layer thickness, e.g. in conveyor systems.

Our experienced integrators implement your wishes and requirements for an inline oil layer thickness measurement quickly and easily.

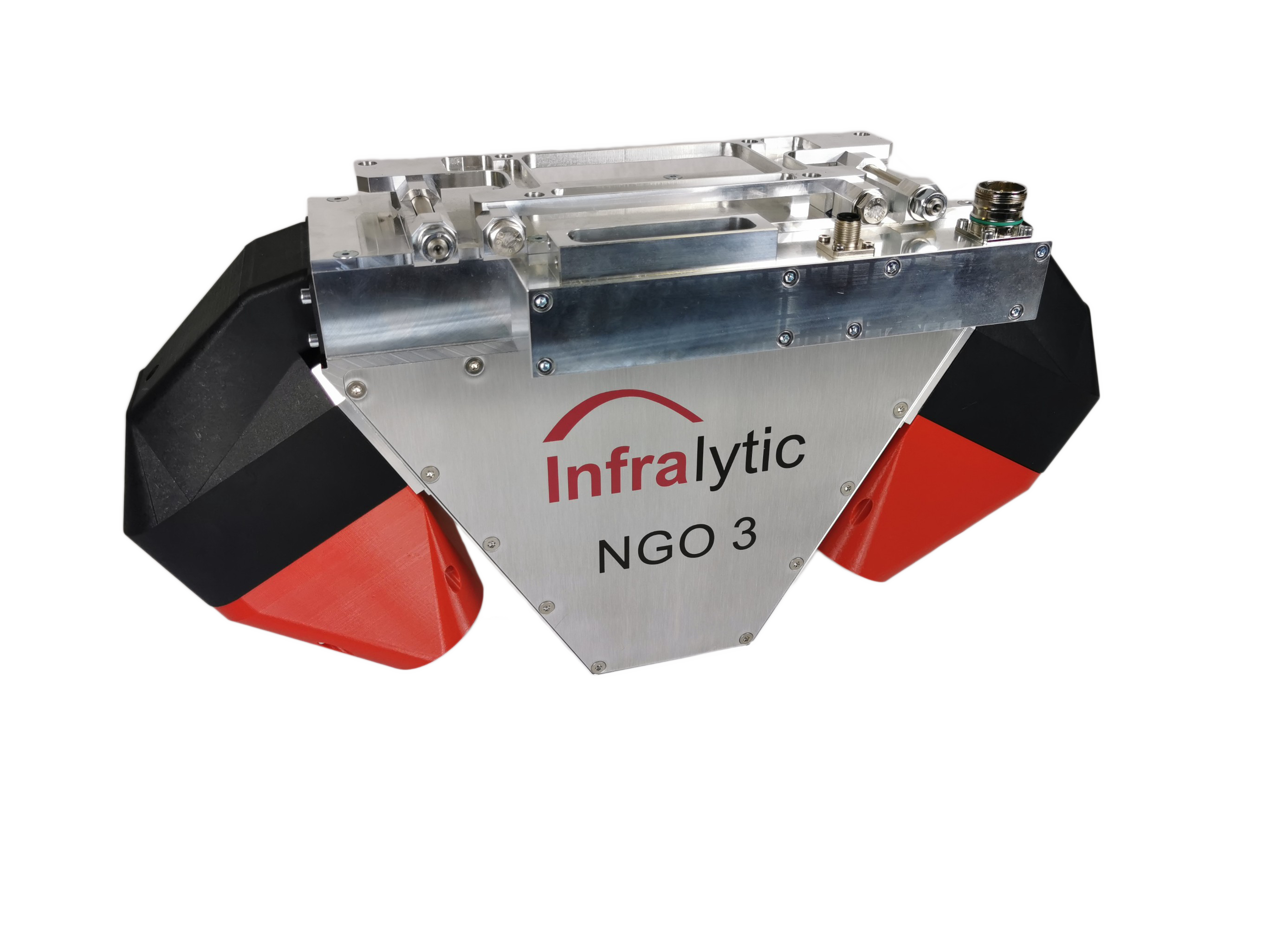

New fast NGO3 measuring head for contact free oil layer thickness measurement. New materials and more complex components require ever greater precision for the forming process. The lubricating film on steel and aluminum sheets must be adapted to the process. Tool life is to be increased, the number of missing parts in production is reduced and efficiency is increased.

With the new and fast inline oil layer thickness sensor NGO3 you continuously determine the oil layer thickness during the process. You receive the measured values in real time. As a numerical value in g / m², as a graph or as a color carpet, you can immediately see the lubricating film covering with which the material is coated.

You can react directly to under- or over-oiling, flat or partial, and avoid faulty production, process downtimes and increased tool wear.

Statistics are created on the collected data of the production, including the oil layer thickness. This allows conclusions to be drawn as to which oiling is used to ensure the highest level of process reliability, the lowest number of missing parts and the longest tool life. For some subsequent processes e.g. coating or painting measures must be ensured and verified that there is no oil.

All calibrations are interchangeable among the devices of the NG group and can easily be transferred to other measuring devices of the NG series. This applies not only to the handheld devices but also to the inline oil layer thickness sensors NGO3. Calibration transfer from the handheld device to the inline sensor and vice versa.

- Calibration transfer between handheld device NG2 and the inline measuring head NGO3

- non-contact measurement in real time

- internal automatic continuous validation review

- color, graphic display

- Independent of the line speed

- Band vibration compensation

- 200 mm safety distance between measuring head and material

- all common oil qualities pre-calibrated

- Independent of oil mixing

- IP 65

The standard measurable oil thickness is between 0.05 and 6 µm (approximately g / m²) oil layer thickness.

Calibrations are standard for:

- untreated cold sheet

- hot-dip galvanized sheet

- fire-aluminum sheet

- electrolytically galvanized sheet (automatic phosphating detection)

- galvannealed

- Aluminium (Millfinish and EDT)

Using the Lambert Beerschen law, the NGO3 determines the oil layer thickness.

The thickness of the oil layer is directly related to the absorption of the light. The light rays penetrate the oil layer twice. The specific wavelengths are partially absorbed by the oil and evaluated. This measuring principle works largely independent of the type of oil, so oil mixtures do not affect the measurement results accountably.

Measurement method:

Infrared spectroscopy

Measuring range:

0.02 - 6 g / m²

Measurement accuracy:

up to 0.7 g / m²: ± 0.025 g / m²

from 0.7 g / m²: ± 3.5 %

Repeatability:

± 5 nm without smoothing (120 Hz)

± 0,8 nm with smoothing

Measurement resolution:

up to 0.01 g / m²

Surfaces:

all that are not extremely shiny e.g.

Cold strip, hot-dip galvanized,

electrolytically galvanized, phosphated,

aluminized ZnMg surfaces, galvanized

Aluminum – uncoated, pre-treated

Lubricants:

Mineral oil, tixotropic mineral oils, hotmelt, waxes,

other organic lubricants after special calibration

Measuring distance:

200 mm + 20 / - 20 mm

Measurement frequency:

default 120 Hz (up to 450 Hz)

Speed off transversing unit:

up to 2 m / s

Ambient temperature:

+ 5 °C to 55 °C

Cleaning interval:

up to 12 months (depending on the environment)

Protecion class:

IP 65

.

3R Technics Slovakia s.r.o.

Mečíková 54

841 07 Bratislava

Slowakische Republik

Mobile: +421-908-60 77 96

Phone: + 421-2-64 76 16 48

e-mail: mar@3R-Technics.com

www.3R-Technics.com

3R Technics GmbH

Technoparkstrasse 1

8005 Zürich

Schweiz

Phone: +41-76-443 13 03

e-mail: info@3R-Technics.com

www.3R-Technics.com

.